What Are the Different Types of Conveyor Belt Systems?

Water treatment companies often use these types of conveyor systems during water treatment processes. Manufacturers may use metal or synthetic fibers to create filter-capable belts. Woven metal belts. Woven belts feature interlinking chains of metal or wiring designed to allow airflow as an item moves along. Businesses commonly use woven belts.

Types of Conveyor System Definition, Application, Working, Uses and Design (2023)

Here are a few environmentally friendly alternatives to give a conveyor belt an afterlife. 1. Sell it. The most obvious and easiest way to dispose of an old conveyor belt is to sell it. Second hand is a popular option in the industry, whether it be conveyors, forklifts or mezzanine floors. If the belt isn't yet showing signs of wear, it can.

Conveyors Types and Uses of Industrial Conveyors

Water treatment companies often use these types of conveyor systems during water treatment processes. Manufacturers may use metal or synthetic fibers to create filter-capable belts. Woven metal belts. Woven belts feature interlinking chains of metal or wiring designed to allow airflow as an item moves along. Businesses commonly use woven belts.

Belt conveyors for waste management and bulk N.M. Heilig

These conveyor structures contain belts for moving bulk sulfur from railcars to storage piles and from the piles to ships.. A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems.A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop.

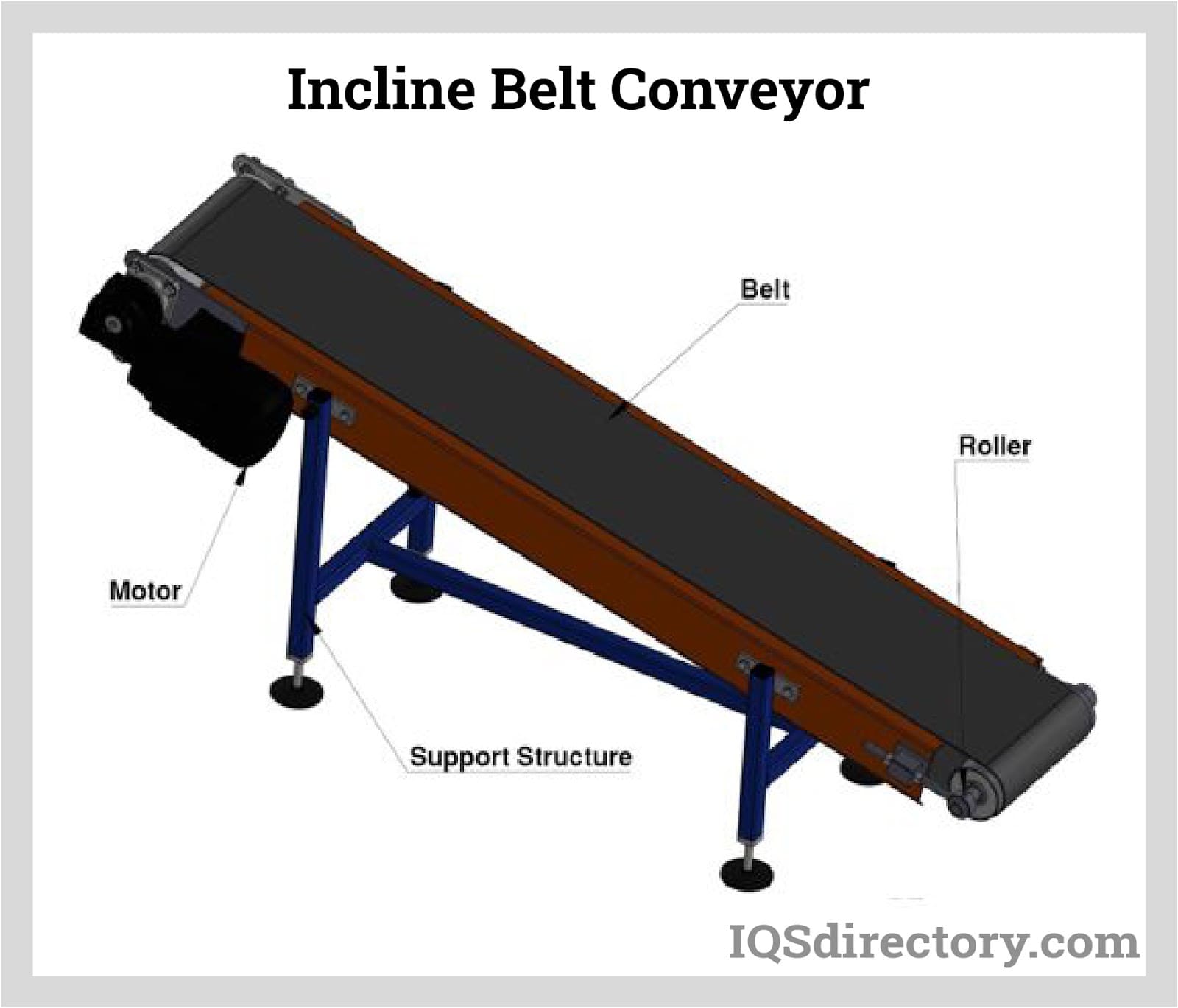

Incline belt conveyor Belt conveyors

This type of belt conveyor uses a curved frame to carry items around corners, make tight transfers, or maximize available floor space. These belts' curves can go up to 180°. True curved conveyors that do not have any straight runs can only use flat belts, as modular plastic belts require straight runs before and after curves..

Why are Conveyor Belts Used? News ch

Conveyor Belts that are used for Industrial Purposes: Almost all of the manufacturers and suppliers were greatly dependent on the manpower before the emergence of industrial conveyor belts. The safety of the workforce and the quality of the product is a major issue under the manual handling of the products. In the current industry-driven.

How Does a Conveyor Belt Work? • Con Belt

These belts optimize productivity. In the food industry conveyors are used to deliver the product to cooking or sealing equipment, then off to packaging. Conveyor Uses "Treadmills are operated by the use of conveyor belts. Check out counters at the grocery store use conveyor belts to move items to be purchased along toward the check out point.

What Is a Conveyor System and How Can It Help Your Operations?

Conveyor belts resemble a band or loop of rollers connected to rotors powered by a motor. The belts can be as narrow as one inch (25 mm) or as wide as five feet (1.5 m), with plastic modular belts as wide as ten feet (3 m). Conveyor belts are made of highly durable and sturdy materials, much like heavy-duty machinery.

Belt conveyor for recycling and bulk handling industry Bezner

Conveyor 23-3/4″ x 25′ x 3/8″- 3ply. $ 162.00. 108 lbs. | FREE SHIPPING | Located in TEXAS. Add to cart Show Details. Page 1 of 45 1 2 3 › ». SAVE 50-75%! USED Conveyor Belting | Water Gaps, Feed bunks, Barn Walkways and More | CHEAP! Ultra durable and strong rubber that hold up to the elements!

What Are The Main Types Of Conveyor Belts Where Are They Used and

Conveyor systems mostly use a rotor to power the belt and drive the pulley. The presence of friction between the rotor and the belt enables the belt to stick firmly to the rotor at all times. Metal rotor and belt. The idler and drive pulley are always maintained in the same direction - either clockwise or reverse - to ensure smooth and.

What is a conveyor belt? LAC Conveyors

A conveyor belt is a mechanical system consisting of a continuous loop of flexible material that is used for the transportation of goods, materials, or products from one point to another. Conveyor belts are a common feature in various industries and serve the purpose of automating the movement of items, thereby increasing efficiency and reducing the need for manual labor.

What Types Of Conveyors Are Used In Industrial Applications JHFoster

Conveyor belts are also used in airports to transport luggage and even passengers on moving walkways. Another unique use is in the entertainment industry where conveyor belts are used to create special effects such as moving stages or props during live performances. Additionally, some sports facilities have installed conveyor belt systems to.

What is a Conveyor Belt LAC Logistics Automation

Power belt conveyor systems can be customized by adding separators, cleats, or sidewalls. Some of the used conveyor manufacturers we supply are: Rapistan, Matthews, Automotion, Alvey, Bestflex, Hytrol, Omni, TWG, Roach, Metzgar, Bushman, Portec, and Ermanco Conveyor. Power belt conveyors may also be referred to as: incline conveyors, belt.

Belt Conveyors Components, Types, Design, and Applications

Conveyor Belt Support: Rollers keep the belt on track and prevent sagging. Driving Unit: Utilizes motors with variable or constant speed-reduction gears. Pulleys: Strategically positioned to control the belt's movement and perform critical functions. Clamping Straps: Used to hold down fixtures and work components.

How Beneficial Mini Conveyor Belts Are To Your Industry Bit Rebels

Roller bed belt conveyors are used mainly where there is hand sorting, assembling, transporting, and inspection. Examples include in: Airport baggage handling; Courier items sorting including postal offices; Flat Belt Conveyor. The flat belt conveyor is one of the most common conveyor types. It is typically used to transport items within a.

Conveyor belt systems for Manufacturing NGS Engineering

Use steel flat pulleys as opposed to winged pulleys. Load when the belt is fully troughed. Make sure the belt is tensioned properly. Be sure all rolling components are clean, rolling, and aligned. When a vulcanized splice can't be used, skive mechanical splices. Belting specifications should be made according to system design and production.